Galets de dérailleur

Galets de dérailleur

Les galets de dérailleur sont le point de départ pour optimiser votre dérailleur. Ils font partie des trois points clés d’optimisation de la transmission, aux côtés des roulements de roues et du boîtier de pédalier. Avec l’une des rotations les plus élevées (environ 800 tr/min) ils constituent un élément majeur pour réduire la friction tout en conservant la qualité de changement de vitesses d’origine. L’utilisation de galets en aluminium apporte une touche haut de gamme à votre vélo, en comparaison avec les galets de dérailleur en plastique.

Fabrication et qualité

Nos galets en aluminium sont usinés en France puis assemblés avec nos roulements dans notre atelier, comme l’ensemble de nos produits CyclingCeramic. Nous utilisons des billes céramiques Grade 3 dans chacun de nos roulements afin de garantir la meilleure qualité et les meilleures performances possibles. Nous employons de l’aluminium 7075, réputé pour son excellente résistance à la fatigue. Cet alliage offre également une meilleure résistance à la corrosion que l’acier. Les galets sont ensuite anodisés et gravés du logo CyclingCeramic. Une attention particulière est portée aux détails et, depuis 2018, nous avons intégré des dents biseautées sur le galet inférieur, permettant un changement de vitesses optimal tout en laissant au galet guide son rôle principal. Afin de garantir une compatibilité parfaite avec tous les modèles, nous avons développé un ensemble de entretoises adaptées à chaque type de dérailleur présent sur le marché. Chaque galet de dérailleur est le résultat d’une longue phase de tests, d’abord en interne puis auprès de nos athlètes partenaires, afin de valider notre cahier des charges reposant sur trois points fondamentaux : qualité, performance et durabilité.

Performance & tests

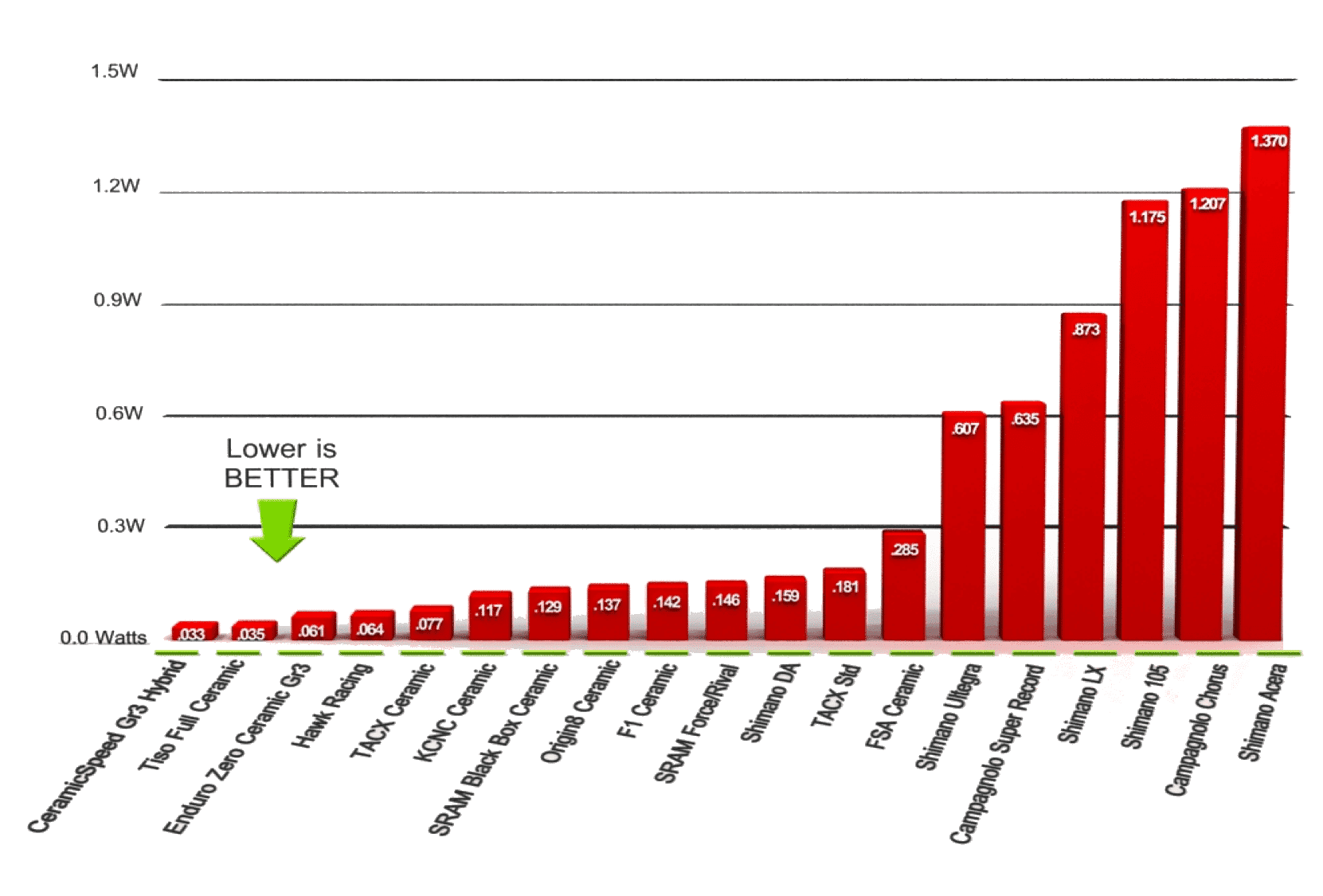

En 2016, CyclingCeramic a soumis ses galets de dérailleur au célèbre laboratoire Friction Facts (depuis racheté par CeramicSpeed). Le test a montré que CyclingCeramic réduit la friction de 72 % en moyenne par rapport à l’ensemble des galets du marché (SHIMANO / SRAM / CAMPAGNOLO). Le test a été réalisé sur une paire de galets de 11 dents lubrifiés avec notre huile et a révélé une friction moyenne de 0,039 W, ce qui les place parmi les galets les plus rapides jamais mesurés par le laboratoire. Le test a été financé par CyclingCeramic afin de comparer nos galets de dérailleur à 19 modèles déjà référencés par Friction Facts. Le laboratoire nous a transmis ses résultats, que nous publions sur notre site, selon le même protocole que celui utilisé par nos concurrents.

Friction Facts a développé sa méthode de travail pour nous de la manière suivante :

- Les galets ont été testés avec une charge de 2 kg, ce qui correspond à la charge exercée sur la transmission pendant le pédalage.

- Les galets ont été réglés à environ 460 tr/min pour les galets de dérailleur, ce qui correspond à environ 95 tours par minute avec un développement de 53 x 11.

Les galets de dérailleur sont testés tels quels, à la sortie de la boîte, ou selon les recommandations commerciales du fabricant.

La précision du test est de +/- 0,001 watt, ce qui en fait l’un des tests les plus fiables jamais réalisés sur une transmission de vélo.

25 mesures sont effectuées chaque seconde du test. - Le test dure environ 10 minutes pour chaque galet de dérailleur et la moyenne de friction est calculée à la fin.

- Ce test est réalisé dans un environnement exempt de toute contamination externe et peut ne pas refléter les performances dans des conditions humides ou lorsque la transmission est sale.