Lab Test

Performance Validation

To validate the performance and durability standards we set, our wax-based lubricants were subjected to extensive testing in our internal test lab. Both our Road Wax (liquid) and Hot Melt Wax were evaluated against a standard factory-applied Shimano chain lubricant, providing a clear baseline for real-world comparison.

The test environment was designed to replicate long-distance riding under demanding conditions. Chains were mounted on an automated drivetrain capable of sustaining a constant 250 watts at a speed of 56 km/h, with no power fluctuation. Throughout the test, a controlled mixture of water and dirt was continuously applied to the drivetrain, simulating extended riding in mixed and contaminated conditions.

Each lubrication system was tested over repeated sessions equivalent to 300 km of riding. At the end of each session, power loss was measured to assess lubricant degradation, contamination resistance, and wash-off. This long-duration approach allowed us to evaluate not only initial performance, but also consistency and durability over time.

The results clearly demonstrate the advantages of wax-based lubrication. While the factory-applied Shimano lubricant showed a progressive increase in power loss as contamination accumulated, both our Road Wax and Hot Melt Wax maintained a significantly more stable power-loss profile across successive 300 km test sessions. This confirms sustained drivetrain efficiency, superior resistance to water and dirt, and long-lasting performance over extended distances.

Understanding chain wear progression

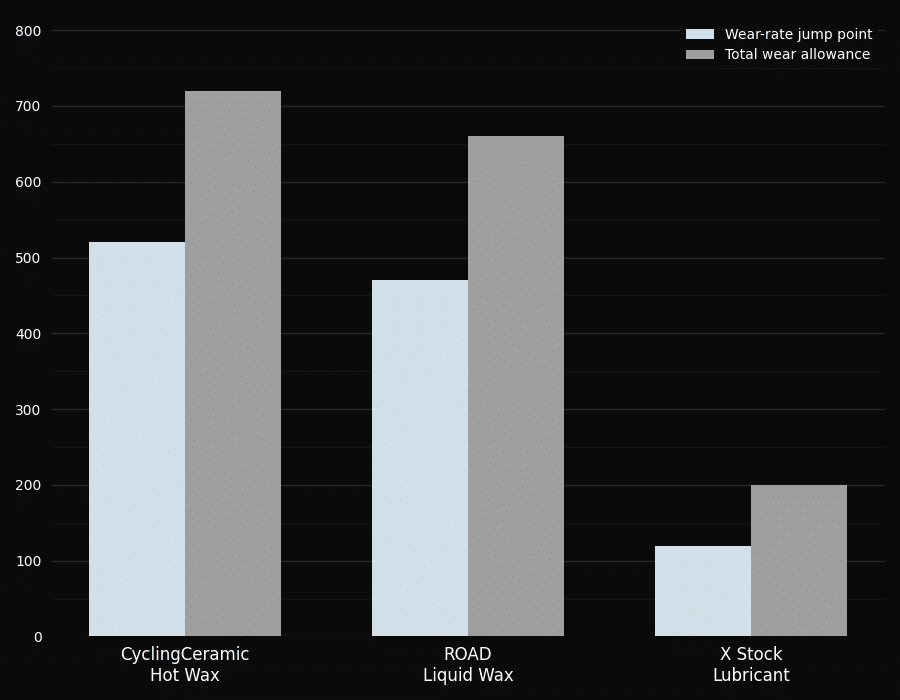

This graph illustrates the progression of chain wear over distance for different lubrication technologies, based on a single application and continuous use under demanding riding conditions.

Chain wear does not evolve in a linear way. As the lubricating film degrades, friction and contamination increase, which leads to an accelerated wear phase. The curvature of each line reflects how well a lubricant is able to maintain a stable protective film over time.

Hot wax (CyclingCeramic)

Hot wax lubrication shows the slowest and most stable wear progression.

The wax creates a dry, solid film that resists contamination and limits abrasive particles from entering the chain articulation points.

As a result:

wear increases gradually,

the acceleration phase is delayed,

the chain remains below the recommended wear limit for a longer distance.

This makes hot wax systems the benchmark for maximum drivetrain longevity.

Liquid wax (ROAD)

Liquid wax follows a very similar wear trajectory, with a slightly earlier acceleration phase compared to hot wax.

This behavior reflects:

good penetration into the chain,

partial solidification of the wax film,

slightly lower resistance to extreme contamination over very long distances.

In practical use, liquid wax offers a high level of drivetrain protection, while being easier to apply and maintain than hot wax systems.

Standard lubricant (oil-based)

The standard lubricant shows a rapid curvature and early acceleration of wear.

Oil-based lubricants tend to:

attract dust and abrasive particles,

retain contamination inside the chain,

lose their protective properties more quickly under real-world conditions.

This leads to an early crossing of the recommended wear limit and increased drivetrain wear.

Key takeaway

Wax-based lubricants significantly slow down wear progression

Liquid wax provides near hot-wax performance with improved usability

Standard lubricants reach critical wear levels much earlier

This comparison highlights how lubrication technology directly impacts drivetrain efficiency, longevity, and maintenance costs over time.

Controlled Contamination Protocol

To ensure repeatable and realistic testing, contamination was applied using a controlled spray system designed to replicate real-world exposure rather than isolated splash events. A calibrated mixture of water and fine particulate dirt was continuously and evenly sprayed directly onto the chain and drivetrain throughout each test session.

The spray pattern and flow rate were carefully regulated to simulate sustained riding in variable conditions such as wet roads, gravel sections, and debris-laden surfaces. This approach ensured that contamination reached not only the outer chain plates, but also penetrated deep into the rollers and link interfaces, where lubrication performance is most critical.

Contamination was applied at consistent intervals and angles to maintain uniform exposure across all test runs. This eliminated variability between sessions and allowed for direct comparison between different lubrication systems under identical conditions.

By using continuous, controlled contamination rather than intermittent immersion, the test more accurately reflects the cumulative effects of water and dirt encountered during long-distance riding. This methodology provides a reliable indication of how effectively each lubricant resists wash-off, maintains film integrity, and protects the drivetrain over extended distances.